Design: Okamura Koki Co., Ltd

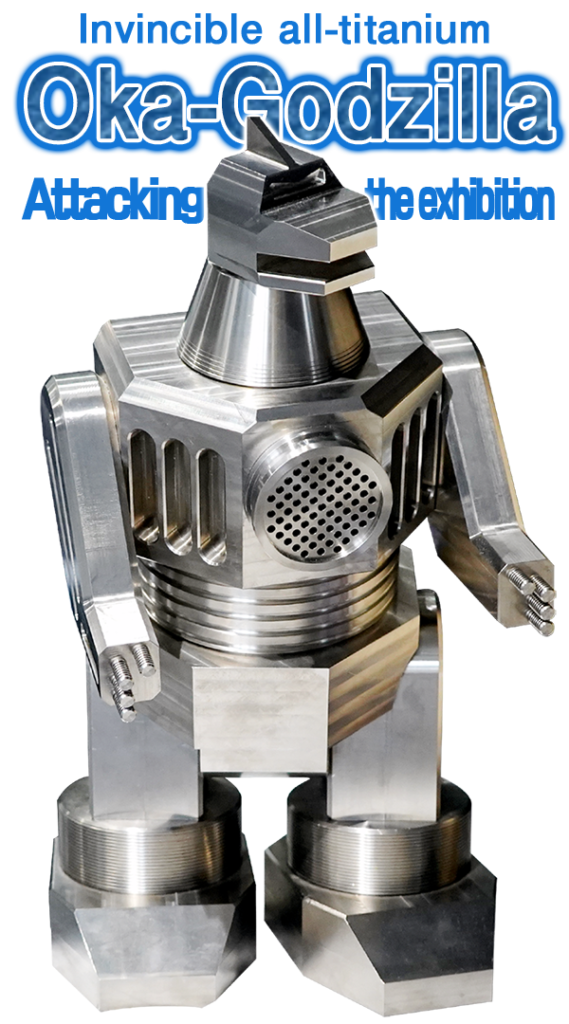

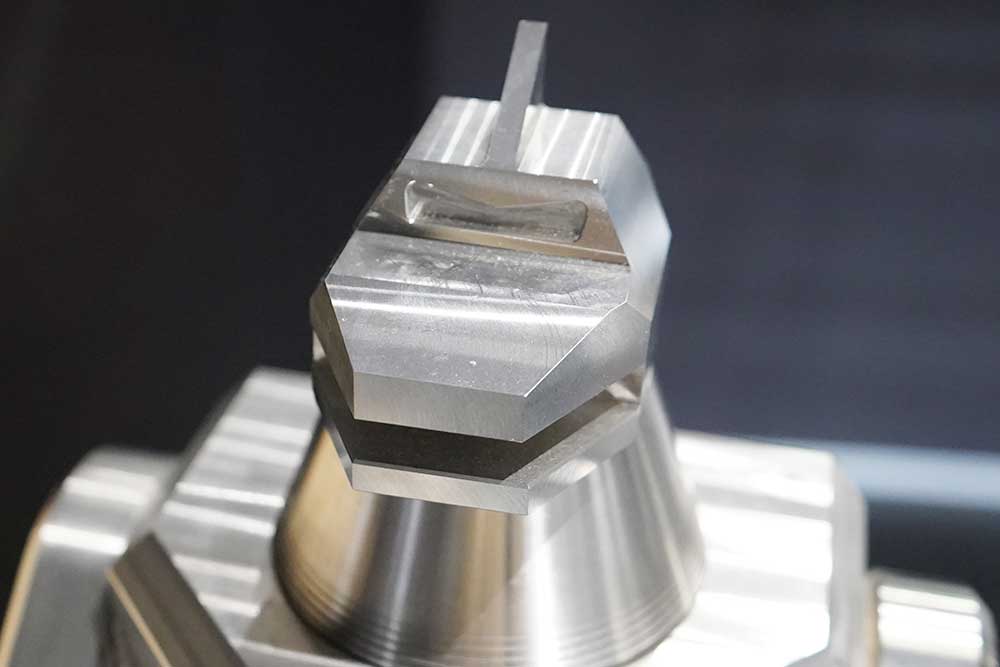

A product born from the desire for improved cutting technology.

This titanium-made invincible monster can cut anything. It is the result of Okamura Machinery Corporation's engineers and their ongoing drive to create high-quality parts and improve their skills.

Okamura Machinery Corporation is one of the 300 Manufacturing Companies selected by the Small and Medium Enterprise Agency of the Ministry of Economy, Trade and Industry.

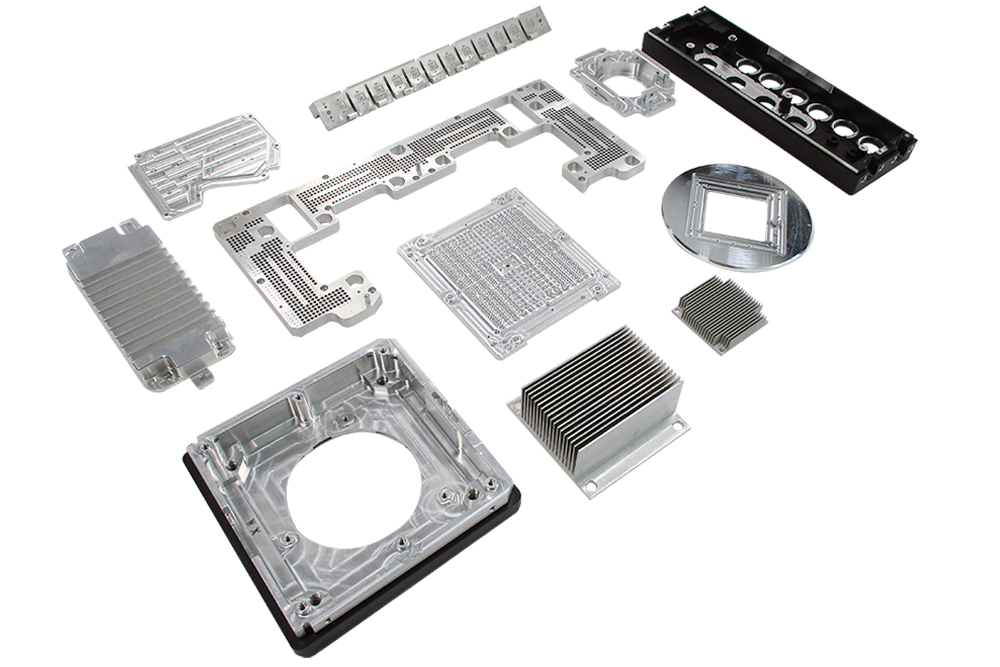

Core technology for cutting

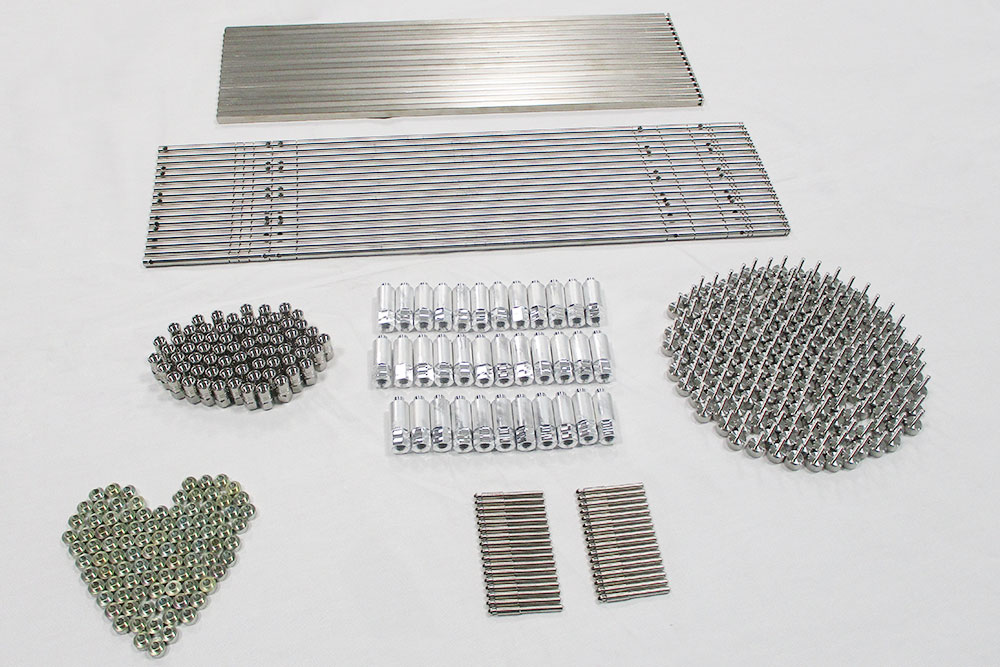

NC automatic lathe processing

We can mass produce round bars from φ2 to 38. One of our strengths is our ability to handle difficult-to-cut materials such as SUS316 and molybdenum steel.

Okamura Koki: High quality, short delivery time, small lot, 3D data design, prototype processing, and mass production.

We harness the collective wisdom and skills of each employee to establish a more effective production system and respond to high-difficulty work with low cost and short delivery time. We accept inquiries by phone and email.

Job Openings for Full-Time Employees

Why not create cutting-edge products at Okamura Machinery?

We are recruiting students from industrial universities,

professionals, and mid-career hires from other industries.