We provide reliability and technology selected by 300 manufacturing companies.

Do you have any of the following problems with your current business partners?

Too many defects, causing "quality issues."

Worries that there might be quality issues as there are too many defective products.

A tedious ordering process

as design and manufacturing are done by different companies.

Difficulty in processing alloys

as orders for hard materials are refused and different companies are used for different materials.

Okamura Koki can solve such problems!

Selected by 300 small and medium-sized enterprises and small businesses.

Okamura Koki-Manufacturing that supports your company

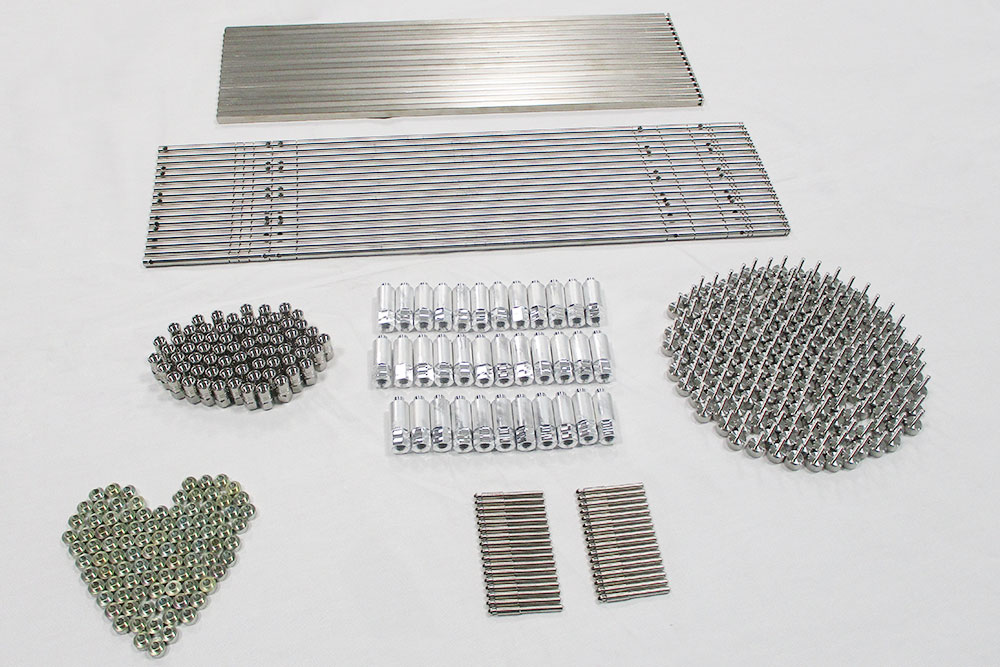

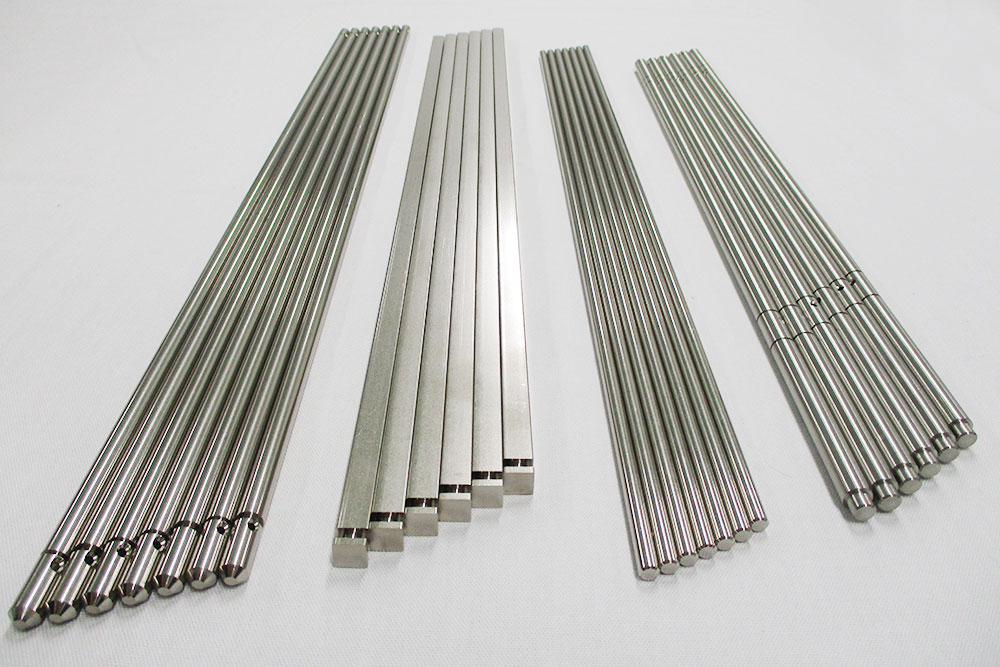

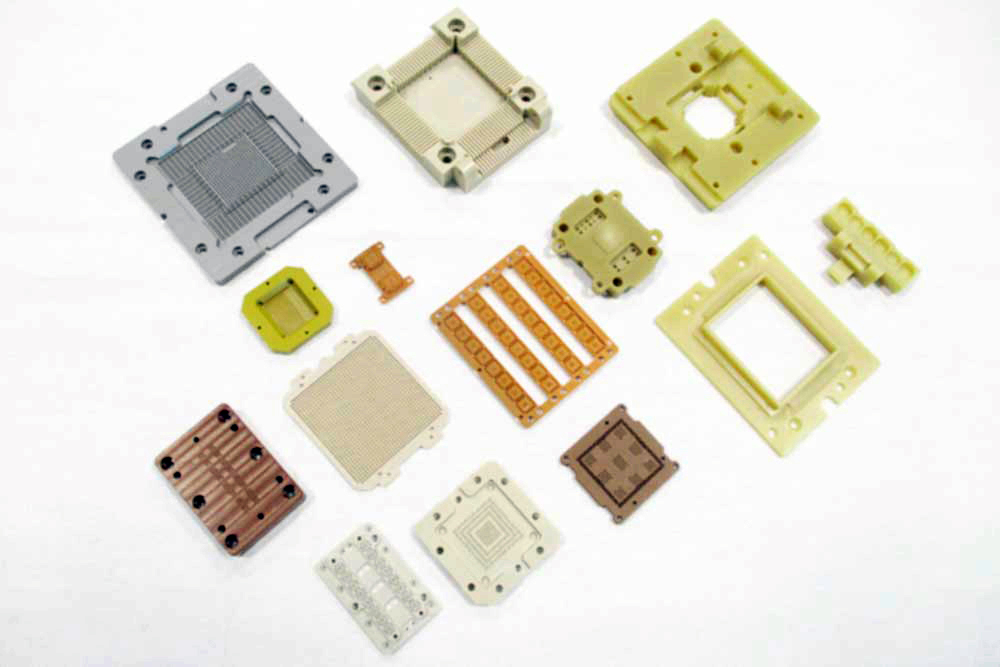

❶ Abundant manufacturing experience with various materials

Cutting hard titanium is another one of our fortes. We also manufacture titanium connector parts used in space projects such as satellites. We handle metals such as titanium/nickel alloys and engineering plastics such as polyimide.

※ We do not we do not handle materials that have a negative impact on our facilities and environment.

❷ Wide range of work sizes and shapes supported

NC composite automatic lathe and NC 5-axis composite turning center processing for φ1 to 320, 5-axis MC processing from ultra-fine hole processing of φ0.02mm to □550×650×500.

❸ Equipment capable of any micro-processing

We can produce even complex connector parts by using multiple mechanical systems. We are particularly experienced at micro-processing and have 2500 types of blades from φ0.02 to 50 in stock with over 30 machine tools.

❹ Various coatings are also possible

We can handle any surface treatment requested by our customers, including painting, anodizing, plating, heat treatment, and Parkerizing. We have business transactions with over 30 surface treatment companies.

❺ 20 years of 3D data programming experience

We have been using 3D data programming for 20 years and have abundant experience in this field. This allows us to carry out an early response to prototype products in-house.

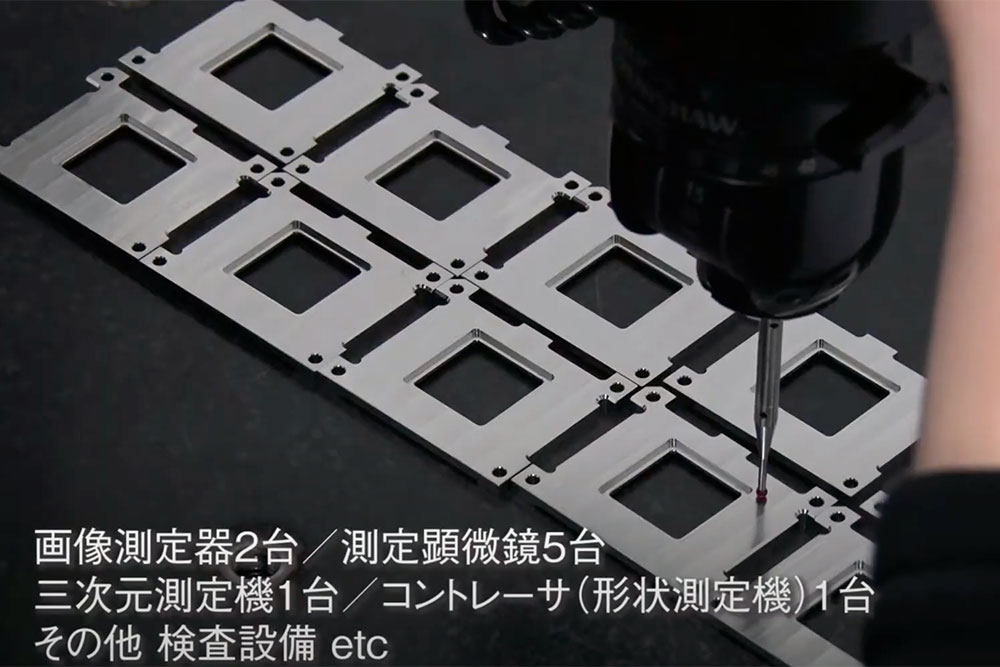

❻Abundant inspection and measurement instruments

We maintain high quality with a well-established quality management system. We inspect all parts before shipment to ensure quality.

We prioritize the wishes and success of our customers.

We have experience in the creation of various precision parts.

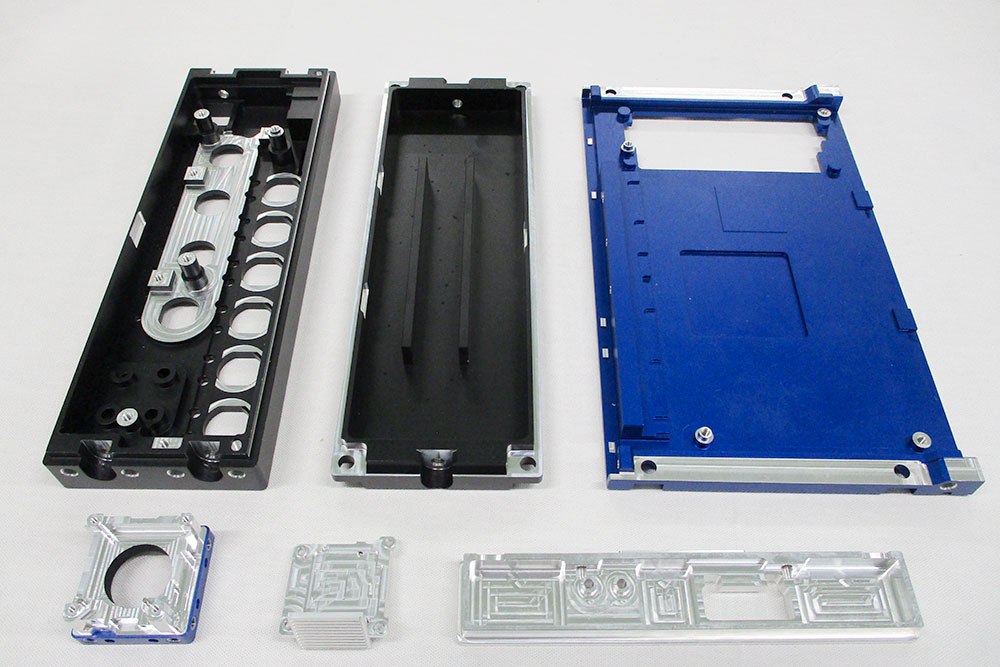

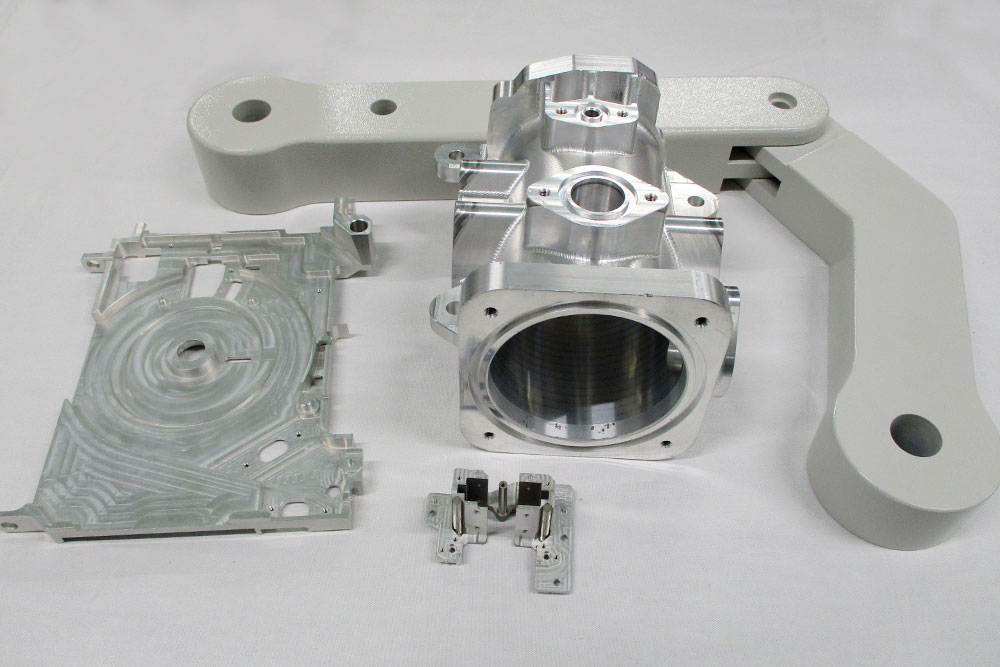

Examples of processed products

Optical equipment parts (NC automatic lathe)

Optical equipment parts (NC lathe)

Optical equipment parts (MC)

Printer equipment parts (NC automatic lathe)

Medical/analysis equipment parts (NC automatic lathe)

Analysis equipment parts (NC lathe)

Infrastructure equipment parts (NC lathe)

Storage/medical/automotive equipment parts (5-axis MC)

Semiconductor parts.

In addition to part production,

we also offer these results

Cost reduction

Improved delivery speed

Strict confidentiality

Joint patents

Design proposals

Inventory management

Why not realize highly precise parts together and support your business?

Realizing highly precise parts and achieving high-quality Japanese manufacturing.

| Company name | Okamura Koki Co., Ltd. |

| Head office address | 808-28 Arcadia 1-chome, Yonezawa-shi, Yamagata-ken |

| Founded | January 1948 |

| Capital | JPY 30,000,000 |

| Number of employees | 40 |

| Representative | Shigeru Okamura, Representative Director |

| Certification | ISO 14000 acquisition in 2016 Business Continuity Plan (BCP) in 2019 Partnership Building Declaration in 2022 |