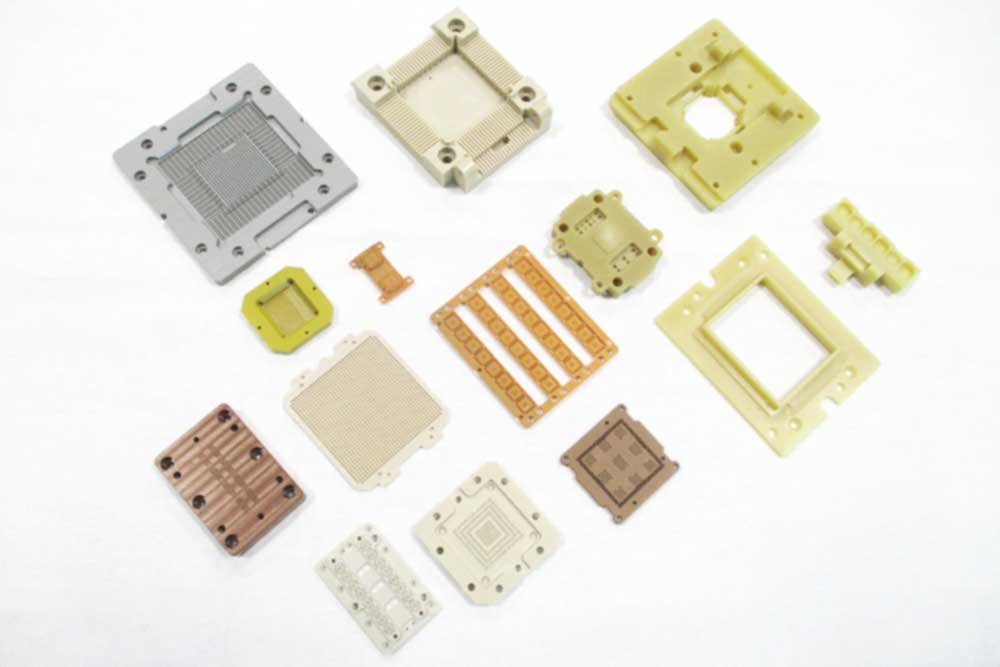

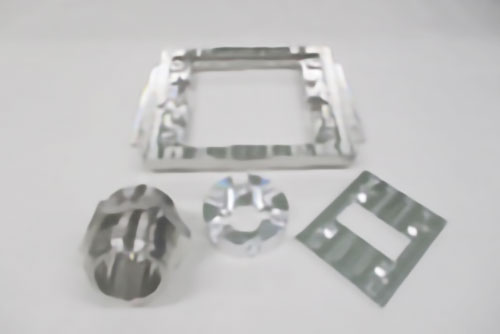

Semiconductor Inspection Socket Parts (MC)

Processed on an MC 3-axis machining center. Various machining works include digging a groove of length 10mm and depth 1.8mm with a φ0.3mm end mill made of hardened resin material containing 30% glass and machining a 0.2mm wall.

Hand Finishing

As fine machining leaves burrs that cannot be removed by machines, skilled personnel responsible for burr removal have developed their own tools and strive for beautiful finishing to satisfy customers.

Various Blasting

Our company has various equipment prepared for blasting purposes, depending on the intended use, including general 1mm metal balls, finer micro-particles, and ice blasting that dissolves upon use to achieve a satin finish.

Cleaning

All parts produced by our company are cleaned thoroughly, except for castings and die castings that are prone to rust. We use a cleaning machine with vacuum function to ensure that even the tiniest holes are sparkling clean.

Equipment Overview

| 設備名 Equipment name | メーカー名 Manufacture name | 型名 Type name | 台数 Num | 補足 Information |

|---|---|---|---|---|

| NC自動盤 NC automatic lathe | 野村精機Nomura Seiki | NN-20BⅢ等 | 5 | |

| シチズンミヤノCitizen Miyano | L20E | 1 | ~φ25 | |

| L20Ⅷ | 1 | ~φ20 | ||

| L32 | 2 | ~φ38 | ||

| L12Ⅹ | 1 | ~φ16 | ||

| NC複合旋盤 NC combined lathe | 日立精機Hitachi Seiki | ハイセル23Ⅱ | 1 | 複合 10インチ |

| 日立精機Hitachi Seiki | スーパーハイセル250 | 1 | 複合 10インチ B軸付 | |

| 中村留Nakamura cuts | SC15O | 1 | 複合 6インチ | |

| 西部機械Nishibekikai | SNC28Pi | 1 | 複合 4インチ | |

| 日立精機Hitachi Seiki | NR-20Ⅲ | 1 | 8インチ | |

| オークマ | LT2000EX | 1 | 複合 8インチ | |

| オークマ | MULTUS B300Ⅱ | 1 | 複合 8インチ | |

| 森精機Monl Seiki | NL1500 | 1 | 複合 6インチ | |

| MC | HERMLE | C3OU | 1 | 5軸 HSK-A63 |

| マキノフライス | D300 | 1 | 5軸 HSK-A63 | |

| ブラザー工業Brother Industries, Ltd | M200X3 | 2 | 5軸#30 | |

| ブラザー工業Brother Industries, Ltd | M200Xd1 | 1 | 5軸#30 | |

| YASUDA | YMC430 | 1 | HSK-E32 MAX40,000rpm | |

| マキノフライス | V22 | 1 | HSK-E32 MAX40,000rpm | |

| オークマ | MB4000H | 1 | 横型 #40 10パレット | |

| マキノフライス | A55 | 1 | 横型 #40 | |

| 日立精機Hitachi Seiki | VK-45Ⅱ | 1 | #50 | |

| 森精機Monl Seiki | VS-5000 | 1 | #40 | |

| ブラザー工業Brother Industries, Ltd | TC-22A-0 | 3 | #30 | |

| ブラザー工業Brother Industries, Ltd | TC-22B-0 | 3 | #30 | |

| ブラザー工業Brother Industries, Ltd | S-2B-0 | 3 | #30 | |

| ブラザー工業Brother Industries, Ltd | S-2C | 1 | #30 | |

| ブラザー工業Brother Industries, Ltd | S500X1N | 2 | #30 | |

| ブラザー工業Brother Industries, Ltd | S500Xd1 | 2 | #30 | |

| ファナック | ロボドリルα-D21SiB5 | 2 | #30 | |

| 自動洗浄機 | クリンビー | CLOVA-4030 | 1 | 炭化水素系ワンバス式真空洗浄乾燥機 |

| NCフライス盤 CNC Milling Machine | 平岡工業Hiraoka Co.,Ltd. | PNO-MSV | 1 | |

| 汎用旋盤 General purpose lathe | 各社Each company | 各種 Various | 1 | |

| ベンチレース Bench lathe | タ力ハシキカイTakahashi Kikai | 101A | 1 | |

| 精密自動旋盤 Precision automatic lathe | タ力ハシキカイTakahashi Kikai | THL-P1XV | 2 | |

| ボール盤・タッピング盤 Drilling& Tapping machine | 各社Each company | 各種 Various | 6 | |

| 平面研削盤 Surface grinder | 三井ハイテックMitsui High-tec, Inc. | MSG-200M | 1 | |

| グラインダー Grinder | 各社Each company | 各種 Various | 4 | |

| サンドブラスト Sandblasting | 不二製作所Fuji Blastech Co., Ltd | SGK-4型 Type-SGK-4 | 1 | |

| 切断機 Cutting machine | アマダAmada Co.,Ltd. | 各種 Various | 2 | |

| 精密低温加熱機 Precision low temperature heaters | サーマルThermal | 1 | ~400℃対応 | |

| ハイスピンカシメ機 High spin caulking machine | ブラザー工業Brother Industries, Ltd | BRI-103 | 1 | |

| 超音波洗浄機 Ultrasonic washing machine | ブロンソン | 2 |

Production Support Equipment

| 生産支援設備 Production Support Equipment | メーカー名 Manufacture name | 型名 Type name | 台数 Num | 補足 Information |

|---|---|---|---|---|

| 3D CAD | ソリッドワークスSolidWorks | 3 | ||

| 3D CAM | MASTER CAM | 3 | 複合旋盤・MC | |

| 2.5D CADCAM | 浜松合同Godo Solution Inc | 2 | ||

| 生産管理ネットワーク Production management network | トップシステムTop system | SPEEDY | 1 | ※生産プロセスを参照 ※Reference PROCESS |

Major Inspection Equipment

| 主要検査設備 Major Inspection Equipment | メーカー名 Manufacture name | 型名 Type name | 台数 Num | 補足 Information |

|---|---|---|---|---|

| 三次元測定器 Three-dimensional measuring device | ミツトヨMitutoyo | BH-V504 | 1 | |

| 画像測定器 Image measuring instrument | ミツトヨMitutoyo | QV202 | 1 | |

| キーエンスKeyence Corporation | IMAGE MAJOR | 1 | ||

| ニコンNikon Corporation | i-NEXIV | 1 | ||

| 測定顕微鏡 Measuring microscope | ミツトヨMitutoyo | MF | 3 | |

| オリンパスOlympus | STM-5 | 1 | ||

| コントレーサー Comte Racer | ミツトヨMitutoyo | CV-3000 | 1 | |

| 真円度測定器 Roundness measuring machine | 東京精密Tokyo Seimitsu Co., Ltd. | Roncom30B | 1 | |

| 表面粗さ測定器 Surface roughness tester | ミツトヨMitutoyo | SJ-301 | 1 | |

| 硬さ試験機 Hardness Tester | アカシAkashi | MVK-H1 | 1 | |

| 測長器 End-measuning machine | ニコンNikon Corporation | 1 | ||

| 実体顕微鏡 Stereomicroscope | NSK | 6 | ||

| 石定盤 Stone surface plate | 武蔵野精機等Musashino Seiki etc. | その他各種 | 6 | |

| 騒音計 Sound level meter | 小野計器Ono Sokki Technology Inc. | LA-1240 | 1 | |

| ピンゲージ Pin gauge | 新潟精機Niigata Seiki | Φ1~15/0.01毎 | 1 |